In the era of Industry 4.0, large-scale industrial operations generate an enormous volume of data every second—from equipment vibration and temperature readings to energy consumption metrics. Turning that raw data into actionable intelligence is the key to maximizing efficiency, reducing downtime, and maintaining safety standards.

Machine learning (ML) is making this transformation possible. By analyzing data collected from connected devices, ML models can detect anomalies, predict failures, and uncover optimization opportunities that would be invisible to human operators. With Cassia Networks’ Bluetooth® gateways at the core of data collection, organizations can seamlessly bridge the gap between industrial hardware and intelligent analytics.

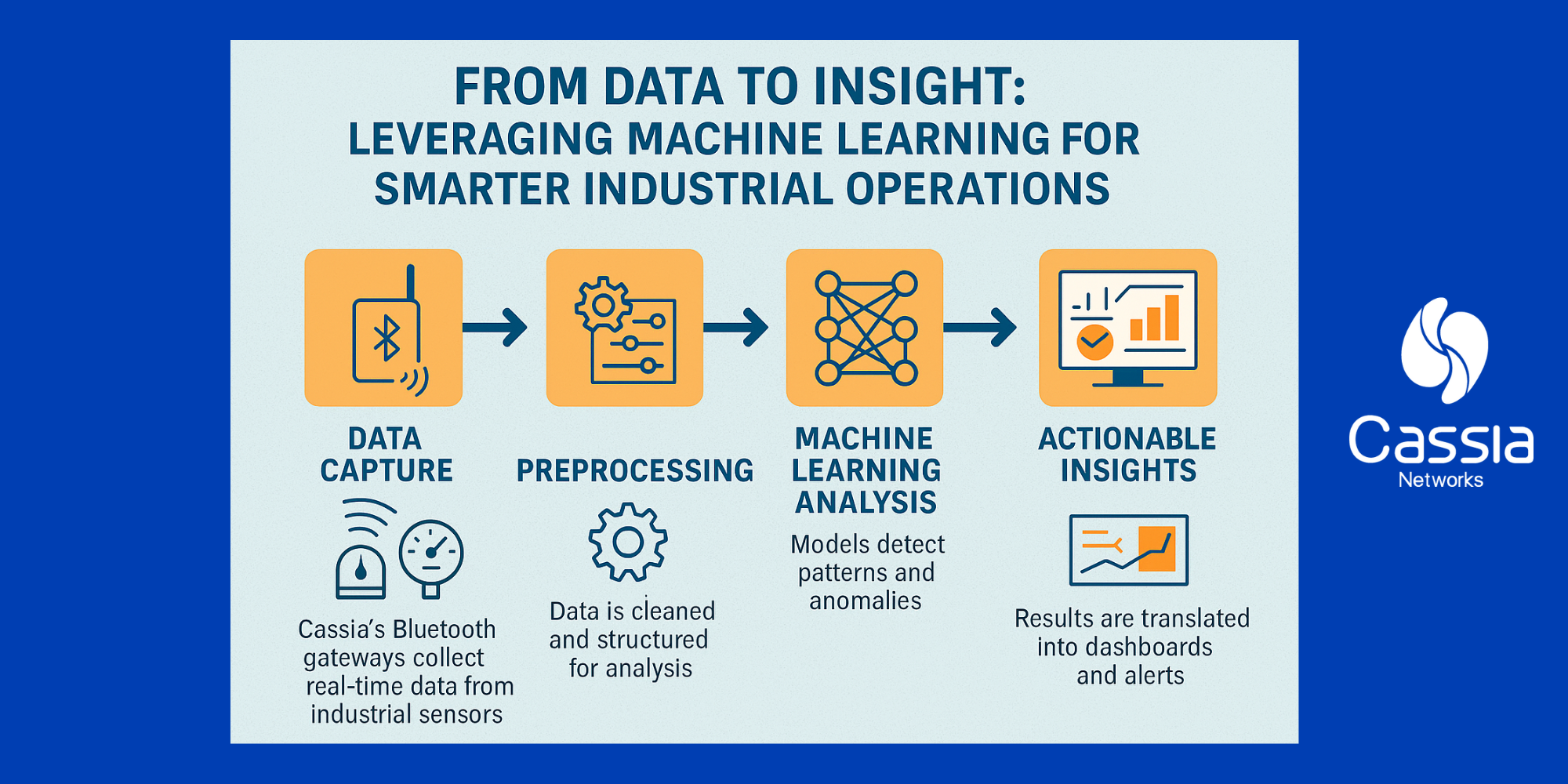

From Data Capture to Actionable Insights

The journey from raw sensor data to operational improvement can be broken down into four critical steps:

- Data Capture

Cassia’s long-range Bluetooth gateways connect to hundreds of wireless industrial sensors at once—collecting real-time readings on vibration, temperature, pressure, humidity, and other key operational parameters. - Preprocessing

Before the data can be analyzed, it must be cleaned and structured. Noise is removed, missing values are addressed, and data streams are synchronized. This step ensures the ML models work with high-quality, reliable data. - Machine Learning Analysis

Trained ML algorithms scan incoming data for patterns and anomalies. These algorithms can recognize subtle shifts in operating conditions that may signal early-stage mechanical issues—long before they escalate into costly failures. - Actionable Insights

The results are translated into easy-to-understand dashboards and alerts. Maintenance teams can prioritize tasks based on risk severity, production managers can fine-tune schedules, and safety officers can respond to hazards before they cause harm.

The Power of Edge Computing

In industrial environments, time is critical. By incorporating edge computing capabilities, Cassia gateways can process and filter data on-site before sending it to the cloud.

This delivers several benefits:

- Lower latency – Critical alerts are generated in near real-time.

- Reduced bandwidth usage – Only relevant, filtered data is transmitted, minimizing network strain.

- Improved reliability – Operations can continue even if cloud connectivity is temporarily unavailable.

Edge intelligence ensures that industrial teams can make faster, better-informed decisions—right where the data is generated.

Practical Use Cases

The integration of machine learning with Bluetooth-connected industrial IoT devices unlocks powerful applications, including:

- Early Detection of Equipment Wear

ML models can identify abnormal vibration patterns in motors or pumps that may indicate misalignment, imbalance, or bearing wear. - Predictive Maintenance Scheduling

By forecasting when components are likely to fail, maintenance can be planned for minimal disruption—reducing both downtime and costs. - Operational Optimization

Analyzing machine runtime patterns can reveal inefficiencies, allowing managers to optimize schedules and energy usage.

Smarter Industrial Operations Start with Better Data

In the competitive landscape of industrial manufacturing, logistics, and energy production, the ability to act on real-time insights is a major advantage. Cassia Networks’ Bluetooth gateways provide the data foundation needed to power advanced machine learning solutions—enabling large industrial IoT deployments to operate more efficiently, safely, and sustainably.

With the right combination of reliable data capture, intelligent analysis, and edge computing, industrial operations can move beyond reactive maintenance into a new era of predictive, proactive, and optimized performance.

Please contact Cassia Networks’ team to schedule a free demo and discuss your projects at sales@cassianetworks.com