In today’s competitive automotive industry, supply chain visibility and asset protection have never been more critical. As manufacturers and suppliers strive to reduce downtime, minimize waste, and enhance traceability, Real-Time Location Systems (RTLS) have become an essential tool. However, when IoT condition monitoring is integrated with RTLS, the result is a powerful combination that goes far beyond simple asset tracking. It delivers real-time insight into the health, status, and environment of critical assets across the supply chain.

1. Enhanced Visibility Beyond Location

Traditional RTLS provides real-time data on the where: the precise location of returnable packaging, tools, parts, or vehicles within a facility or across logistics networks. By adding IoT condition sensors, businesses gain insight into how those assets are being handled, stored, and transported.

Sensors can monitor:

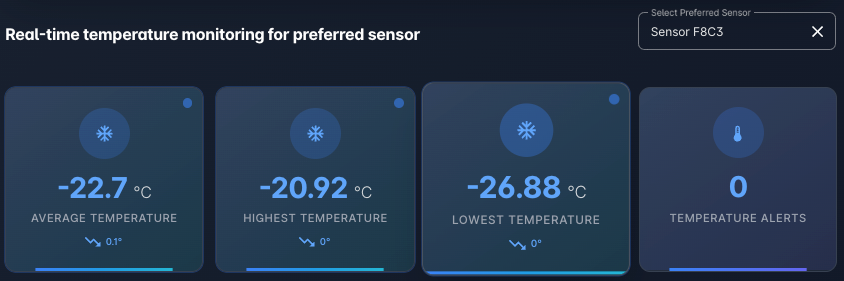

- Temperature and humidity to ensure climate-sensitive parts and materials remain within acceptable thresholds.

- Shock and vibration to detect rough handling or potential damage during transit.

- Tilt or orientation to identify when packaging or containers are mishandled.

Together, RTLS and IoT monitoring offer a full picture of both asset location and condition, allowing companies to act proactively instead of reactively.

2. Reducing Damage and Quality Issues

In automotive manufacturing, even minor deviations in temperature, vibration, or impact can cause part degradation or failure. For example, sensitive electronic control units (ECUs) or painted components can be damaged if exposed to improper conditions during transport.

By combining RTLS and IoT condition monitoring, suppliers can receive instant alerts when environmental or handling thresholds are exceeded. This enables immediate intervention, rerouting a shipment, investigating a specific container, or flagging a batch for inspection before defective components reach production lines. The result is higher product quality and lower rework costs.

3. Streamlined Root Cause Analysis

When quality issues arise, identifying their origin can be time-consuming. Was it a supplier issue, a packaging problem, or mishandling during transport?

With RTLS + IoT data, every asset carries a digital footprint of both its journey and the conditions it experienced. Manufacturers can easily trace back the exact location, time, and cause of an incident, whether it was a vibration spike at a loading dock or a temperature fluctuation in a warehouse. This detailed insight simplifies root cause analysis, strengthens supplier accountability, and supports continuous improvement efforts.

4. Optimized Asset Utilization and Maintenance

Beyond preventing damage, IoT condition data can be used to monitor the wear and tear of reusable packaging and equipment, such as racks, bins, and containers, commonly used throughout the automotive supply chain.

By tracking impact frequency, vibration exposure, or usage cycles, companies can predict when assets are nearing the end of their useful life and schedule maintenance or replacement proactively. This predictive maintenance approach extends the lifespan of high-value assets and reduces unplanned downtime.

5. Supporting Sustainability and Cost Efficiency

Sustainability is a growing priority across the automotive sector. The combination of RTLS and IoT condition monitoring contributes directly to environmental and cost goals by:

- Reducing waste from damaged goods and discarded packaging.

- Enabling data-driven route optimization that cuts fuel use and emissions.

- Supporting a closed-loop returnable packaging system, ensuring containers are tracked, maintained, and reused efficiently.

These benefits align with the automotive industry’s broader shift toward greener, smarter logistics.

6. Data-Driven Decision Making

The integration of RTLS and IoT creates a unified data ecosystem that transforms raw sensor readings into actionable insights. With real-time dashboards and analytics, supply chain managers can:

- Identify trends in damage or environmental deviations.

- Optimize handling procedures and packaging designs.

- Make informed decisions about supplier performance and logistics partners.

This data-driven approach turns the supply chain from a reactive network into a proactive, self-optimizing system.

Incorporating IoT condition monitoring into an RTLS solution represents a major step forward for the automotive supply chain. It provides a deeper layer of intelligence, one that not only tracks where assets are, but also how they are performing and what risks they face in real time.

The result is a more resilient, efficient, and sustainable supply chain that reduces losses, ensures product integrity, and delivers measurable ROI across operations. For automotive manufacturers and suppliers seeking to stay ahead, the fusion of RTLS and IoT is no longer a luxury. It’s a strategic necessity.

To learn more about how Cassia Networks can enable your RTLS solution using Lamplight Logistics, reach out to sales@cassianetworks.com to get connected with our team members.

To learn more about Lamplight Logistics, reach out to team@lamplightlogistics.com to get connected with their team.