Investing in RTLS may sound like a technological luxury, but in reality, it pays for itself quickly through reduced losses, increased operational efficiencies, and better utilization of assets. In this post, we break down the return on investment (ROI) of using RTLS to manage Returnable Transport Packaging (RTPs).

The Hidden Costs of Mismanaged RTIs

The Hidden Costs of Mismanaged RTIs

Before we dive into the savings, let’s look at the costs:

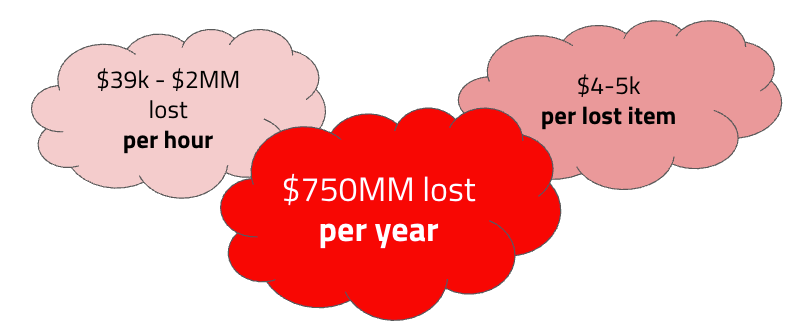

- RTP shrinkage (loss or theft) can result in hundreds of thousands of dollars annually.

- Overstocking “just in case” leads to capital tied up in unused assets.

- Manual tracking increases labor costs and error rates.

- Production delays when RTPs aren’t available at the right time.

- Single-use packaging, including both purchasing and disposal.

________________________________________

________________________________________

How RTLS Improves the Bottom Line

1. Asset Recovery and Loss Prevention

With RTLS, assets that once disappeared into the supply chain can now be located and recovered quickly. Historical location data also helps hold partners accountable.

2. Labor Cost Reduction

Automated inventory tracking eliminates the need for manual counts or barcode scans, freeing up your team for higher-value tasks.

3. Right-Sizing RTI Fleets

RTLS provides accurate usage data, allowing companies to optimize the number of containers in circulation and avoid overproduction or underutilization.

4. Faster Turnaround Times

Improved visibility shortens asset cycles, reduces dwell time, and increases asset availability — all of which translate into smoother operations.

5. Elimination of single-use packaging

When the correct returnable packaging can’t be located, delaying production is too costly, so single-use packaging is used as a stopgap. The cost to purchase AND dispose can be massive. With RTLS, this cost can be reduced or eliminated.

Example: A Real ROI Story

A leading beverage distributor implemented RTLS to manage its keg fleet. Within 12 months, they:

- Reduced keg loss by 40%

- Cut new keg purchases by 30%

- Saved over $500,000 in procurement and labor costs

________________________________________

How to Calculate Your ROI

To estimate RTLS ROI:

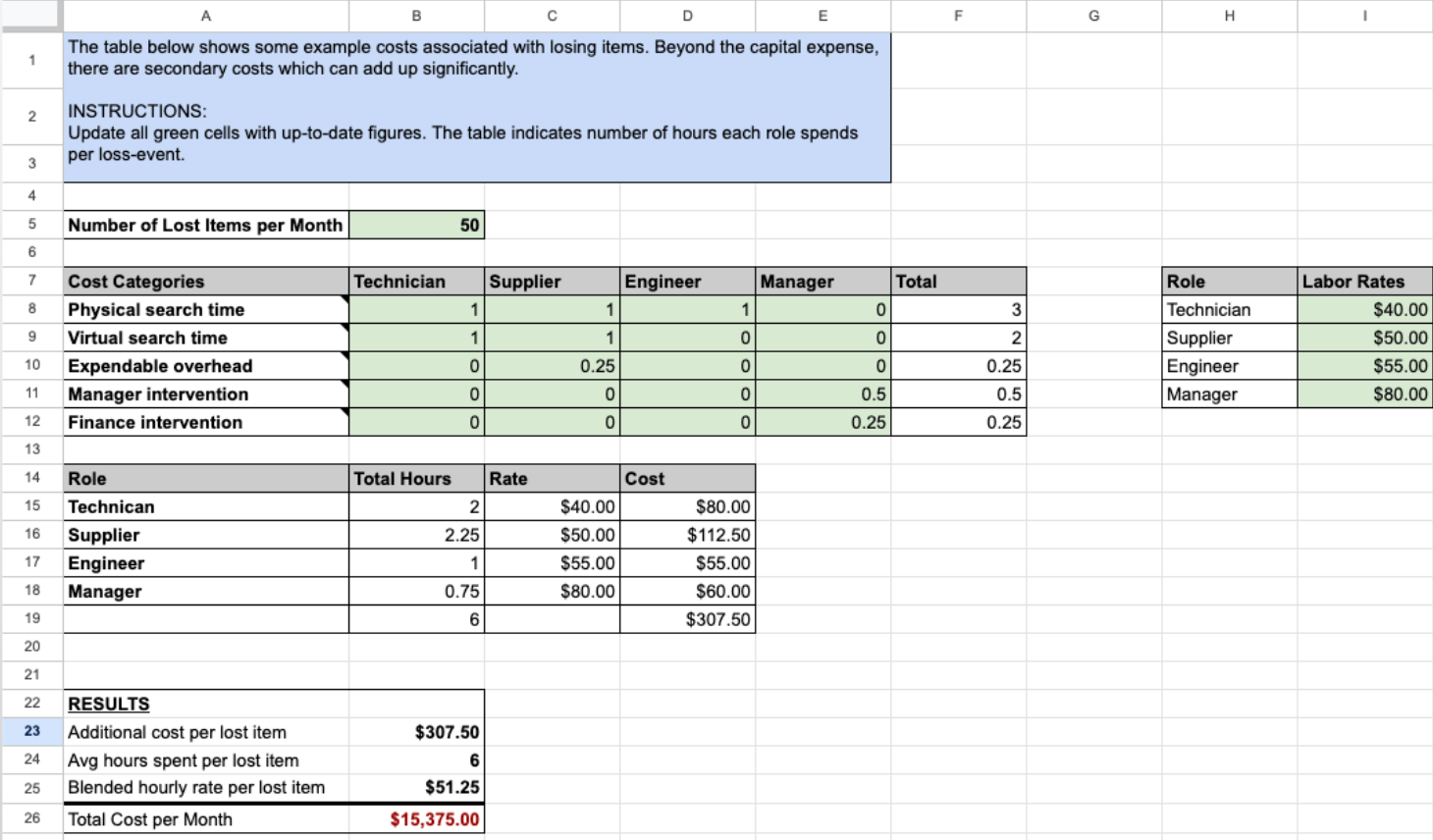

- Determine the baseline costs (e.g., annual losses, labor, procurement). This includes obvious costs like capital expenditure on new packaging, but also secondary costs like search time, re-ordering time, and more.

- Estimate reduction percentages based on industry benchmarks or pilot data.

- Subtract RTLS deployment and maintenance costs.

Lamplight Logistics has tools like the cost calculator below to help identify the true cost of missing items. We help companies craft a business case by utilizing our expertise and experience to uncover hidden costs and help calculate real ROI.

________________________________________

________________________________________

Let’s talk about how deploying RTLS can help your company save money today. Give us a shout at team@lamplightlogistics.com.

To learn more about how Cassia Networks can enable your RTLS solution using Lamplight Logistics, reach out to sales@cassianetworks.com to get connected with our team members.

Next Post: Learn how RTLS also helps reduce idle inventory and dwell time through smarter location intelligence.