Joint Solution Brief

BACKGROUND AND CHALLENGES

Inductosense is a UK-based company specializing in the design and manufacture of advanced ultrasonic sensor technologies for internal corrosion and erosion monitoring. Monitoring pipe wall thickness is essential to maintaining pipeline integrity in industrial environments. Corrosion and erosion gradually reduce pipe wall thickness, increasing the risk of leaks or catastrophic failures—jeopardizing personnel safety, environmental protection, and asset integrity.

This case study describes how Inductosense in collaboration with Cassia Networks resolved a complex challenge for a customer in the oil and gas sector located in the U.S. Midwest. The customer sought a comprehensive solution to tackle three primary challenges:

- They required an online monitoring system, but the site’s remote location did not have a wireless infrastructure.

- They experienced leaks and equipment failures, which resulted in unplanned downtime and caused substantial daily profit losses.

- Conventional inspection methods were very expensive and insufficient for effectively monitoring erosion at the oil rig. The customer needed a more accurate and efficient solution to measure pipe thickness remotely and continuously.

SOLUTION

Inductosense deployed its WAND (Wireless and Non-Destructive) Online 4G Solution which was ideally suited to address the challenge. A key component of the solution was the integration of Cassia Networks’ X2000 Bluetooth IoT Gateway. Cassia’s X2000 is designed for demanding industrial environments, offering long-range Bluetooth connectivity up to one-kilometer, bi-directional communication, and Edge processing capabilities for custom applications. To support hazardous environments, Inductosense also utilizes the ATX2000—a ruggedized version of the X2000 certified for Zone 2, Zone 22, and Division 2 hazardous areas.

Figure 1: X2000

Figure 2: ATX2000

The seamless Bluetooth coverage enabled remote, accurate and real time monitoring of internal erosion using WAND Remote Data Collectors (WAND-RDC) and the Cassia X2000 gateway. WAND Online 4G Solution required no existing on-site wireless infrastructure and was simple to deploy. After initial validation on a mature well pad, the customer expanded the system to a new site to study the correlation between flow rate and sand erosion rate—a critical metric for optimizing production without compromising pipeline integrity.

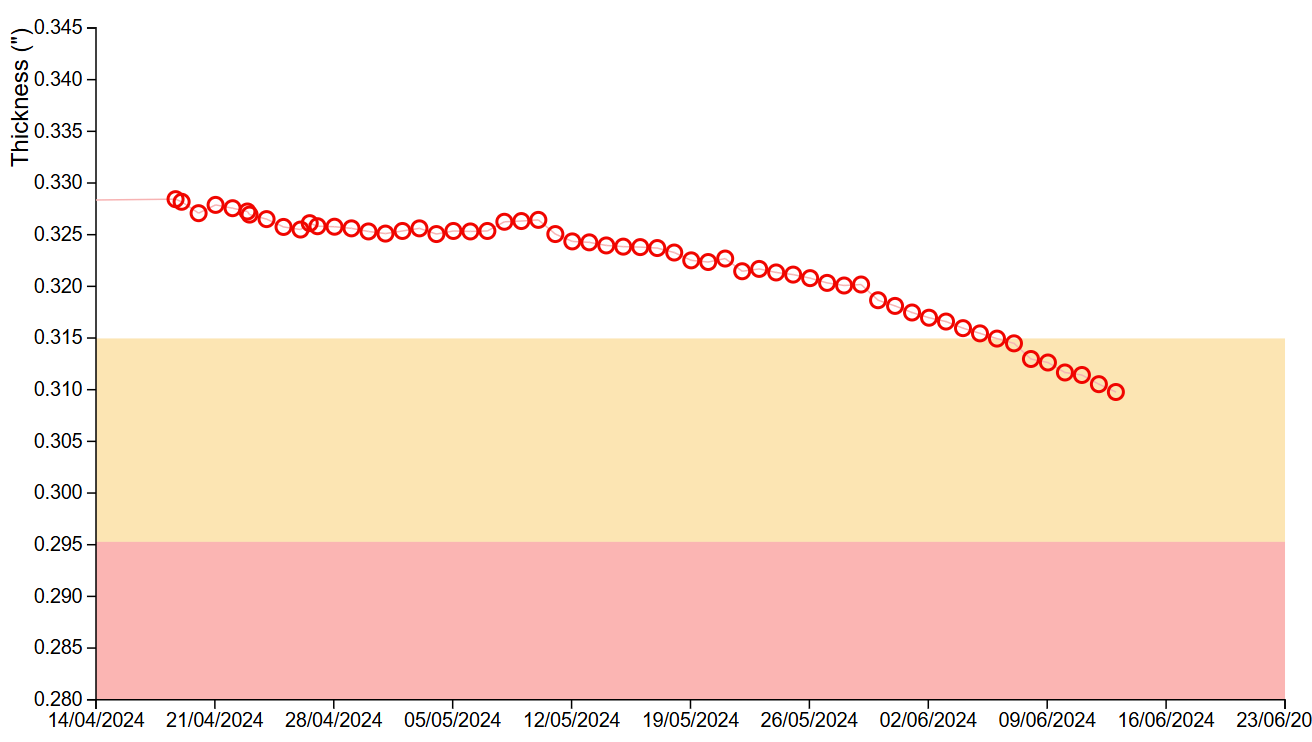

A total of 54 WAND sensors and 9 WAND-RDCs were installed across the site on sand traps and gas processing units (GPUs), with support from local partner Precision Group. A pre-configured WAND-Gateway, powered onsite, automatically connected to all WAND-RDCs. The complete solution is illustrated in the accompanying diagram (see below). Operators could remotely monitor daily wall thickness, as shown in Figure 4, eliminating the need for on-site personnel deployment.

Figure 3: WAND-Online Solution System diagram

Figure 4: Thickness loss trend line over 2-month period. Orange section represents warning thickness set by the user. Red section is the end-of-life thickness set by the user.

RESULTS

The implementation of the Inductosense WAND-Online 4G System delivered significant benefits:

Reduced Downtime, Increased Efficiency – Remote monitoring with daily measurements enabled early detection of wall thinning. Moreover, the customer could maximize production while monitoring the effect on the integrity of the equipment and minimizing costly shutdowns or repairs.

Provided Reliable, Actionable Data – The WAND-Online 4 G System consistently provided accurate information regarding the state of the equipment, allowing the management to make informed maintenance decisions.

High Return on Investment (ROI):

- 840 hours of personnel time saved in the first month alone, recouping the cost of investment.

- Increased oil well production by 50% per day, resulting in $43,000 in additional daily income.

Another important benefit of ongoing equipment inspection in the oil and gas industry is the enhancement of worker safety. According to the Occupational Safety and Health Administration (OSHA), the U.S. agency responsible for workplace safety, oil and gas well drilling and servicing activities involve a wide range of equipment and materials, each posing potential hazards. As scientific research highlights, “recognizing and controlling hazards is critical to preventing injuries and deaths.” In response to these risks, OSHA recommends a variety of safety protocols, including regular equipment inspections and comprehensive worker safety training.

(Retrieved from Safety Hazards Associated with Oil and Gas Extraction Activities: https://www.osha.gov/oil-and-gas-extraction/hazards)

CONCLUSION

The Inductosense WAND system, combined with Cassia Networks’ Bluetooth IoT infrastructure, showcases the powerful benefits of wireless, real-time monitoring. From oil and gas to manufacturing and hazardous environments, this solution supports productivity, safety, and operational excellence. Its scalability and ease of use make it ideal for a wide range of industrial applications.

ABOUT

About Cassia Networks

Cassia Networks is the leading provider of enterprise Bluetooth IoT solutions. Our patented technology enables reliable, long-range, and multi-device Bluetooth connectivity, with built-in edge processing and locationing capabilities. We are dedicated to solving the connectivity, management, and locationing challenges of enterprise IoT networks and making IoT deployment easy.

Learn more at: www.cassianetworks.com

Contact: sales@cassianetworks.com

About Inductosense

Founded in 2015 and headquartered in Bristol, England, Inductosense is the developer of the patented WAND system—an embeddable wall thickness monitoring technology that delivers highly accurate and repeatable measurements at significantly lower cost and time than traditional methods.

Inductosense serves industries such as oil and gas, nuclear, aerospace, renewables, and chemicals—helping customers enhance safety, reduce maintenance costs, and support digitalization and net-zero goals. The company also offers technical support, training, and custom R&D, including innovations in subsea and high-temperature applications.

Learn more at: www.inductosense.com